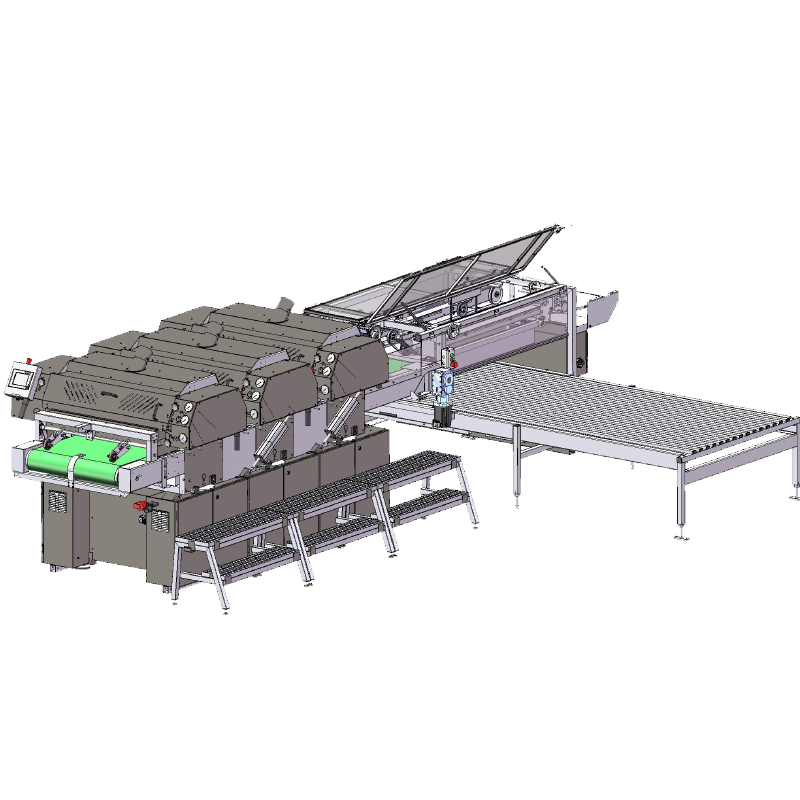

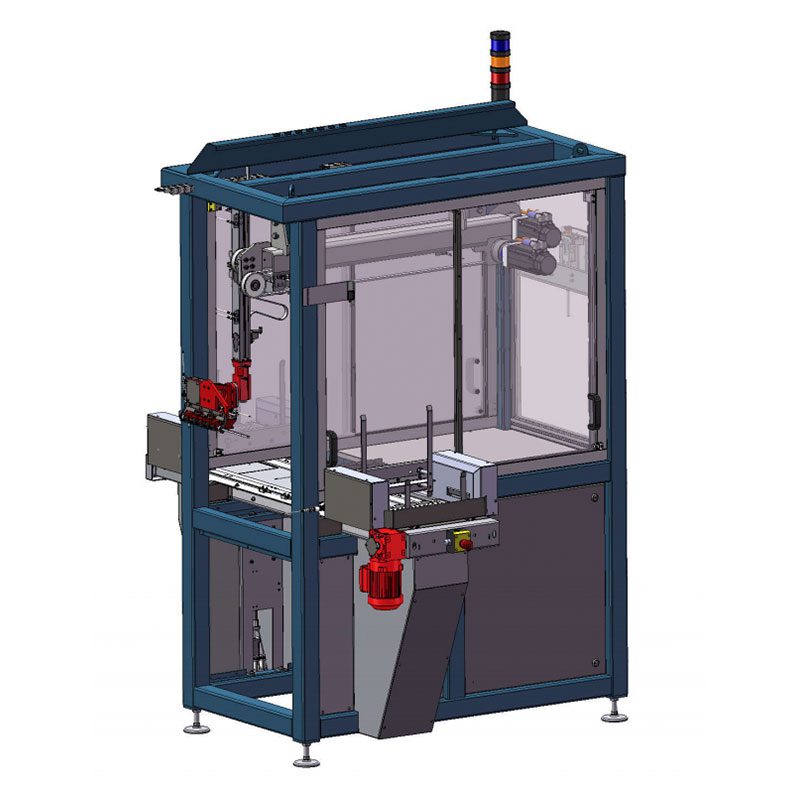

Jute and Polypropylene bag printing equipment

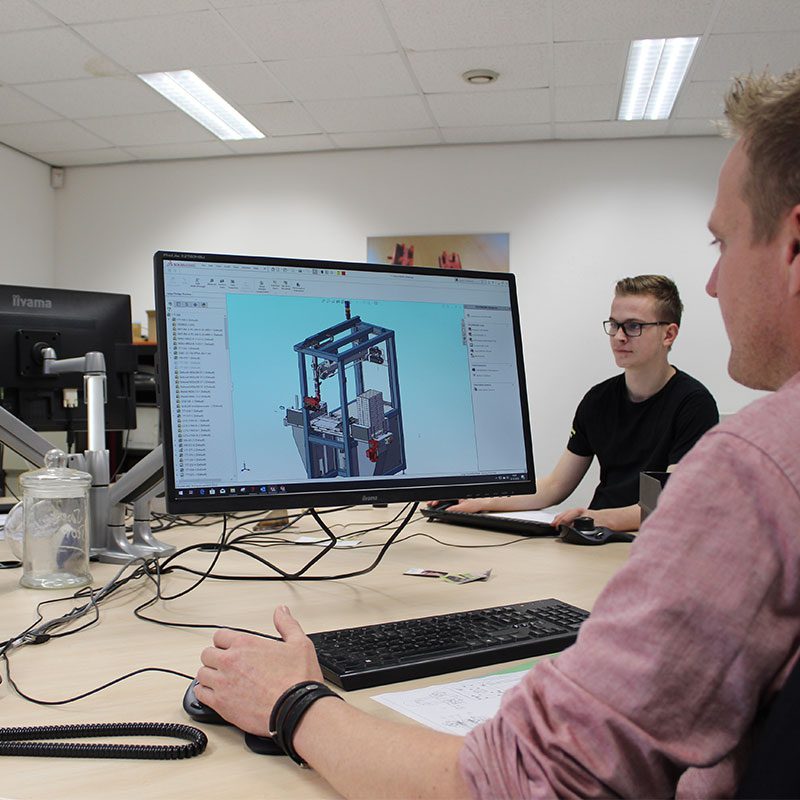

The Autonational Bagprinting Equipment division is the number one equipment supplier in the bag printing industry. We develop and manufacture equipment solutions for anything to do with bag printing. All our machines are equipped with the newest technologies, such as full servo motor drive. With the help of our extensive experience and our excellent engineering department, we have perfected the servo motor technology, allowing our machines to be both fast and highly accurate, while being thoroughly reliable too.

In addition to tuning our equipment to the client’s needs, we incorporate a high degree of ergonomics and user-friendliness in our designs. For instance: we use central control panels that allow the operator to operate all machine functions from a single spot.

We offer:

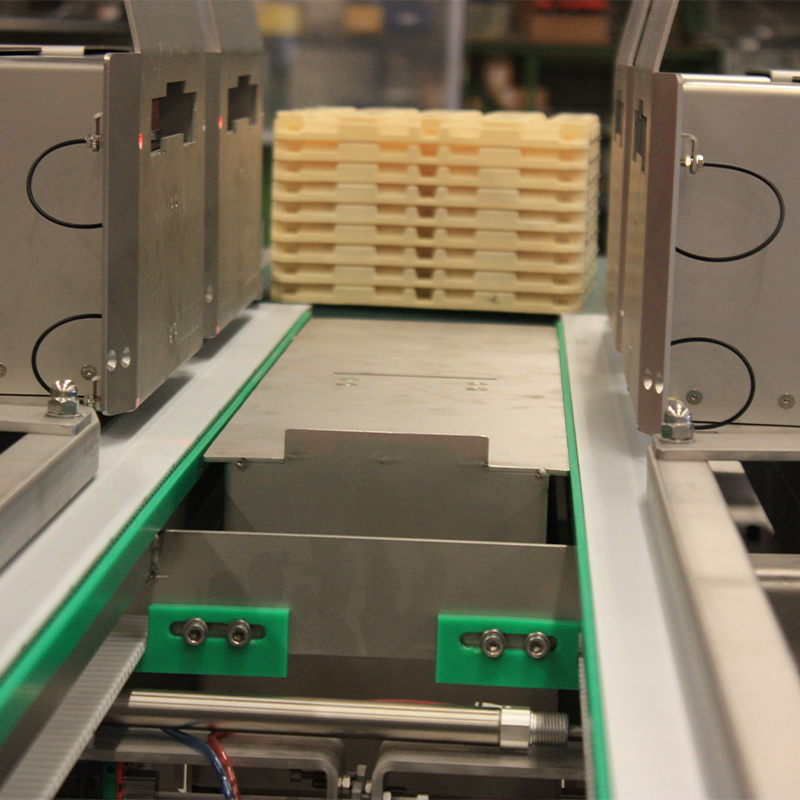

– Robot inserters

– Printing units

– Flipping units (two sided printing)

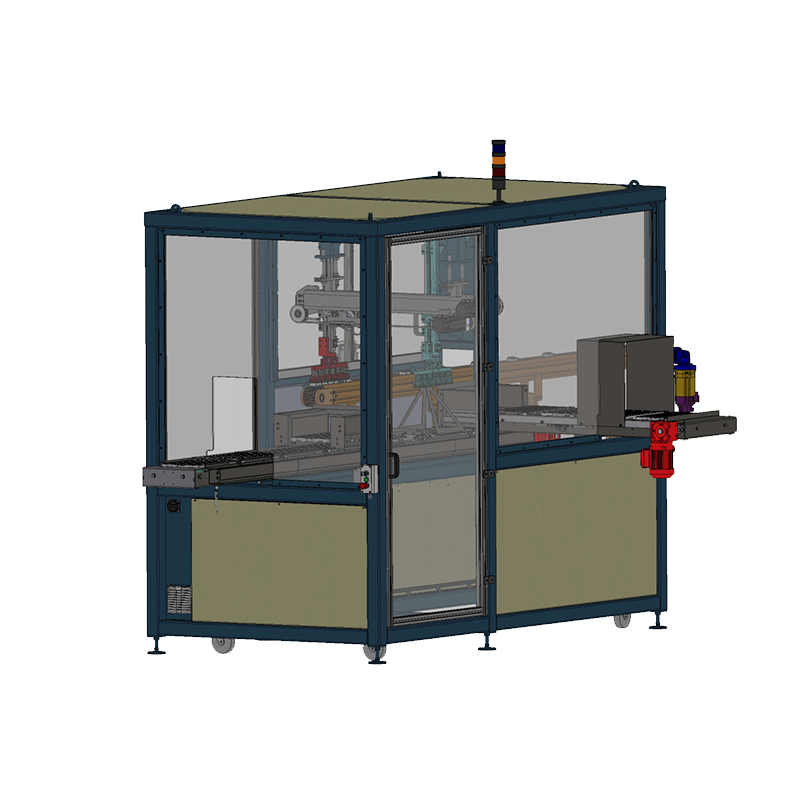

– Stacking units

These modules can be joined together in any order, thus creating a fully functional printing line that allows an unlimited number of colour runs.

Options:

In addition to a combination of the standard modules we also offer custom printing lines that meet any additional wishes of the client. This includes printing lines that accommodate special printing surface dimensions, multiple colors or printing lines that incorporate other kinds of equipment.